How to Choose the Right Pneumatic System Components.

Consider a powerful machine that works solely on air, rather than fuel or electricity. That is the brilliance of pneumatic systems. These systems use compressed air to make objects move, lift, spin, and perform with speed and precision. They can be seen everywhere, from factories to workshops, quietly carrying out heavy-duty tasks.

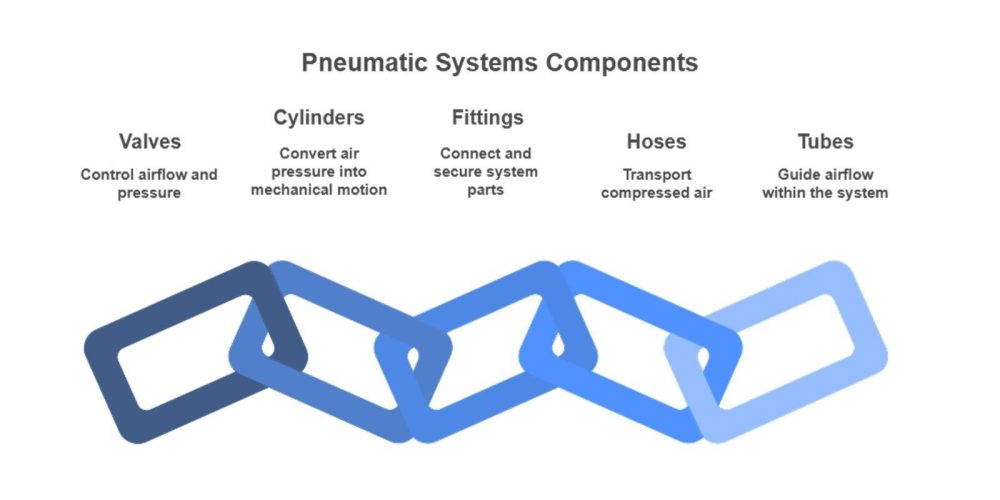

These systems are built around pneumatic system components. These components include valves, cylinders, fittings, hoses, and tubes, which all function together in conjunction. Machines, like the human body, rely on organs to carry out their functions. When these components are picked right, the system as a whole becomes more efficient, safe, and durable. If you’re seeking for high-quality components and skilled guidance, reputable pneumatic dealers in Coimbatore can help you get started with the ideal configuration for your requirements.

What is a pneumatic system?

Pneumatic systems use compressed air to power machines and tools. It generates motion by pushing air via tubes, valves, and cylinders. These systems are employed in factories, workshops, and other businesses because they are clean, quick, and simple to operate.”

Why Choosing the Right Components Matters

When it comes to building or maintaining a pneumatic system, the components you choose matter more than you think. A faulty element might lead to leaks, decreased performance, or even system failure. That’s why choosing the correct size, type, and material is critical.

Using suitable pneumatic system components also prevents energy waste. Poorly fitted components may allow air to escape, forcing the system to work harder and consume more power. With the proper configuration, you can maximize the performance of your system while saving time and money.

Quick advice: Always select parts that fit the requirements of your specific system. Don’t guess—measure and match precisely.

Understanding Compressed Air Lines.

Your pneumatic system’s compressed air lines function similarly to its blood arteries. They carry the air from the compressor to every tool and part that needs it. If these lines are weak or poorly set up, the system won’t perform at its best.

It is critical to utilize high-quality, resilient lines that can withstand air pressure. Even a little crack or hole might cause the entire system to stall or fail. Regular inspections and proper installation ensure that your airflow is smooth and sturdy.

Tip: Inspect your compressed air lines on a regular basis for leaks, cracks, and pressure drops. Early discovery of faults ensures that your system continues to function normally.

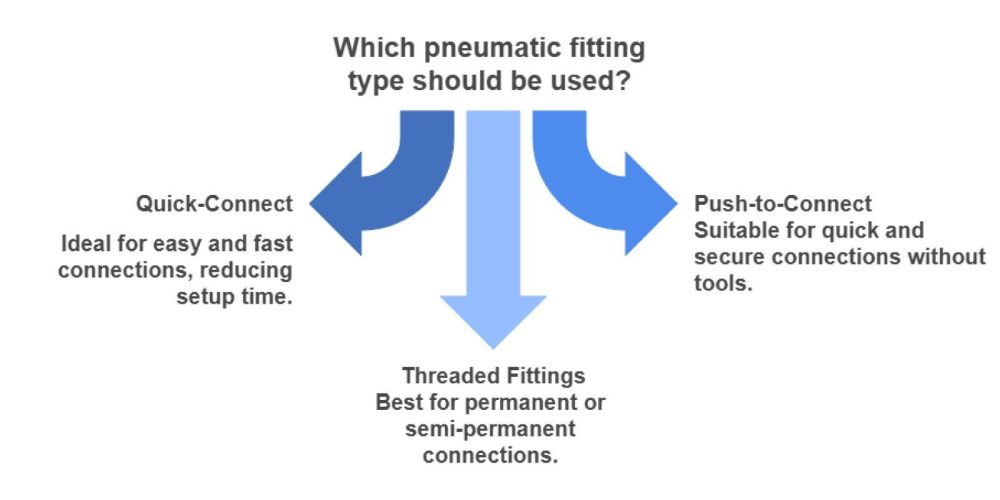

Types of Pneumatic Fittings You Should Know

The fittings are modest yet formidable. They connect the various components of your system, keeping everything together and the air sealed in. There are various pneumatic fitting types, each serving a distinct purpose. Some typical fitting types are quick-connect, push-to-connect, and threaded.

Choosing the proper type prevents leaks and keeps air flowing where it should. Mismatched fittings might result in pressure loss or even damage to your equipment over time. Knowing your fittings can save you a lot of issues later.

Helping hint: Use the appropriate pneumatic fittings for the work to avoid loose connections and waste air.

How to Choose the Right Tubing and Fittings

Tubing and fittings work together to efficiently transport air throughout your system. To avoid leaks, the tubing must be the proper size and material, and the fittings must fit correctly.

When deciding, consider what your system requires. Is it moving a lot? Then, flexible tubing might be ideal. Is the pressure high? Then go with stronger materials. Together, tubing and fittings form the channel that allows your system to breathe properly.

Smart Move: Always choose tubing and fittings depending on pressure, temperature, and the degree of flexibility required for your system.

Air Compressor Hose Basics

An air compressor hose links the compressor to the rest of your system. It needs to be strong, flexible, and able to handle high pressure. If your hose is low-quality, it could burst or crack, stopping your system cold.

Hoses come in a variety of lengths and materials. The best choice for you is determined by how and where you intend to use it. Choosing the incorrect hose can result in airflow concerns or even accidents.

Heads-Up: Choose an air compressor hose that is appropriate for your work environment, and inspect it on a regular basis for wear.

Matching Components with Your Air Needs

Different tools and machines need different air flow and pressure. If your system gives too much or too little air, things won’t work right. Matching your pneumatic system components to your air needs helps avoid these problems.

Begin by determining what pressure and flow each instrument requires. Then, ensure that every component of your system, from the compressor to the pneumatic compression fittings, can supply just that. It is the key to ensuring seamless operation.

Pro Tip: Don’t make assumptions about your air requirements; instead, check the tool’s specs and choose components that meet or exceed them.

Choosing the Best Pneumatic System Components for Your Job

Every job is different. Some applications necessitate heavy-duty components, whereas others require precise, lightweight parts. When selecting the best pneumatic system components like pneumatic cylinders, keep your job’s pressure level, temperature range, space needs, and material compatibility in mind.

Material considerations are also relevant. Plastic parts, for example, may not resist high temperatures, but metal parts may be too heavy or rigid. The right materials and standards for your work environment can make all the difference.

Best Practice: Before making a purchase, consult your machine’s manual and specs. It tells you exactly which components will work best.

Do you require assistance in finding the best fit? Noblemart offers a list of trusted janatics dealers in Coimbatore.Shop for high-quality items that are appropriate for your job.

Common Mistakes to Avoid When Purchasing Pneumatic Parts

One common mistake is selecting the cheapest parts in order to save money. Low-cost parts are frequently less durable or perform poorly. You wind up spending more on repairs and replacements.

Another mistake is presuming the size or type without checking. An incorrect fitting or hose might result in poor performance, wasted air, or even system failure.. A little research goes a long way. Connecting with reliable janatics dealers in Coimbatore can help you avoid these errors by guiding you toward the right, high-quality components.

Avoid This: Invest in quality and double-check sizes and compatibility before buying. It saves you time and effort later.

Keeping Your Pneumatic System Components in Shape.

Maintenance is essential for making your system last. Dust, oil, and moisture can accumulate and clog or harm components over time. Cleaning your system and replacing damaged parts ensures that it runs smoothly.

Also, inspect the seals, valves, and connections. Tighten loose parts, replace cracked tubing, and ensure that everything works properly. A little correction today prevents a larger problem later.

Maintenance Tip: Schedule regular system checks. A little attention keeps things running like new.

When to Replace Your Air Compressor Hose

The air compressor hose wears out over time, even if it looks fine. Cracks, stiffness, or swelling are signs it’s time to swap it out. Don’t wait for complete failure; it can be dangerous.

Inspect the hose on a regular basis, especially if it’s in a hot or high-traffic region. Replacing it before it bursts saves time and prevents accidents.

Please repair your air compressor hose as soon as it shows signs of deterioration.

Note: Replace your air compressor hose as soon as it shows signs of damage. It is safer and smarter.

Conclusion:

Every part in a pneumatic system matters—from compressed air lines to tubing very part in a pneumatic system matters—from compressed air lines to tubing and fittings. These aren’t just pieces; they are the heart of how your machines breathe and move. Choosing the correct pneumatic system components improves performance, decreases breakdowns, and saves you money in the long term.

When each component is properly selected and frequently maintained, your system will work smoothly and consistently, just as it should. It prevents frequent problems such as air leaks, tool failures, and wasted energy. And the good news? You don’t have to be a professional to do it well.

Start by determining the precise specifications for your tools. Look for dependable components, including high-quality air compressor hoses, appropriate

pneumatic fitting types, and long-lasting pneumatic compression fittings. Remember to check for leaks or wear and tear on an ongoing basis.

Leave a Comment

Your email address will not be published. Required fields are marked *